China Cooks Meat Processing Factory – Slaughtering and cutting conveyor line – Bomeida

China Cooks Meat Processing Factory – Slaughtering and cutting conveyor line – Bomeida Detail:

Pig dividing line

The pig carcass after cooling and deacidification enters the pre-segmentation area from the unloading device, and the front, middle and hind legs of the carcass after being cut by the circular saw enter their respective fine-segmented areas, and the finely-segmented products are uniformly transported to the sorting line. , online can be sorted according to the sales order combined with the product category. After sorting, it can be divided into two channels according to the product category: the direct distribution part is directly transported to the distribution area by weighing and labeling, and the gold inspection machine (fresh or frozen) ; The other part that needs to be refinished is directly transported to the finishing area, such as the small ribs, pork chops, buns, plum blossoms, high-quality front leg meat, tenderloin, crispy ribs and other products in the table above. Meat machine, peeling machine, shredding machine, dicing machine and other equipment for processing. In addition, such as fine meat slices, large steaks, etc., need to be frozen again to the core temperature of -2 °C and then processed again in a chopper, slicer, etc. After careful processing, the meat products include short ribs, pork chops, cheese bones, plum blossom meat, fine front ham, tenderloin, crispy ribs, fine steaks, large ribs, pork chops, fixed bones, cucumber strips and fine hind legs Meat, after being palletized by a continuous modified atmosphere packaging machine, after passing through a metal detector, weighing and labeling, is put into a turnover box according to the sales order and transported to the distribution area.

Sheep dividing line

The sheep ketone body is pushed to the cutting workshop through the track, and it is hung manually. The meat of the part is sent to each processing station through two deboning and dividing conveyors. The upper layer of the deboning and dividing line is designed with a bone lifting conveyor and a bone collection conveyor. The picked bones are transported to the bone transport area for reprocessing. The trimmed and cut products are transported to the weighing and packaging area for finishing and packaging.

Cattle dividing line

1.Change the beef two-part to four-part;

2.Finely cut and trim, finely cut, transport and pack large pieces of beef;

3.Trim part of the meat to make fat beef

Parameters

| Product size | According to your need | Belt material | POM or PU belt |

| Other | 304 stainless steel | Power | According to need |

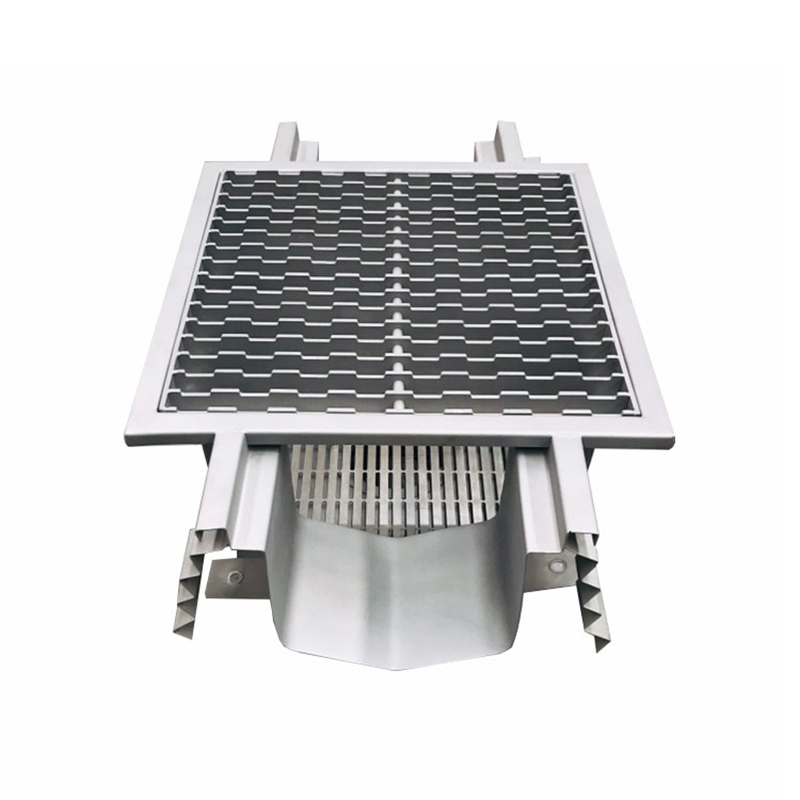

Details Picture

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for China Cooks Meat Processing Factory – Slaughtering and cutting conveyor line – Bomeida, The product will supply to all over the world, such as: Seychelles, Accra, Barbados, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.